Universally and Securely Fastened

(PresseBox) ( Furtwangen, )

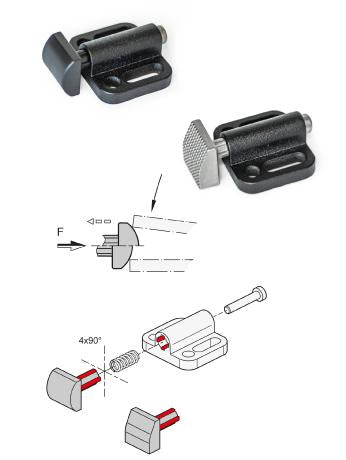

Many things that hardly draw notice are nevertheless of elementary importance within the overall context. For example, it would be hard to conceive building jigs without side thrust pins to hold parts – which is precisely why Ganter developed the series GN 415. They are more compact and adaptable than the previous versions.

Side thrust pins are practically indispensable elements of jig construction and are available in a wide range of variants. Nevertheless, there are applications that demand particularly compact designs that should also be easy to adapt to different requirements. These are exactly the situations Ganter had in mind with the new standard parts family GN 415.

GN 415 is available in three sizes between 22 and 39 millimeters wide, each with two spring strengths. The two available slide types and the wedge-shaped or cylindrical, rounded thrust pad not only hold parts with side pressure but also exert an additional downward force. All thrust pads can be rotated around their long axis in 90-degree steps to optimally adjust to the part geometry – this is as simple as loosening the central slide screw. The thrust pads are also available in a POM plastic version as well as in stainless steel with smooth or textured pressure pad for better grip. The latter type is produced by injection molding of metal and is therefore subject to only minimal measurement tolerances.

The great value Ganter places on simple and universal handling is on display in the method of fastening implemented for the black zinc die cast housing. Two normal bores are supplemented by slots that allow the housing to be shifted by a generous 4.5 to 13.5 millimeters.

More information on Ganter standard parts can be found in the internet at:

www.ganternorm.com

Side thrust pins are practically indispensable elements of jig construction and are available in a wide range of variants. Nevertheless, there are applications that demand particularly compact designs that should also be easy to adapt to different requirements. These are exactly the situations Ganter had in mind with the new standard parts family GN 415.

GN 415 is available in three sizes between 22 and 39 millimeters wide, each with two spring strengths. The two available slide types and the wedge-shaped or cylindrical, rounded thrust pad not only hold parts with side pressure but also exert an additional downward force. All thrust pads can be rotated around their long axis in 90-degree steps to optimally adjust to the part geometry – this is as simple as loosening the central slide screw. The thrust pads are also available in a POM plastic version as well as in stainless steel with smooth or textured pressure pad for better grip. The latter type is produced by injection molding of metal and is therefore subject to only minimal measurement tolerances.

The great value Ganter places on simple and universal handling is on display in the method of fastening implemented for the black zinc die cast housing. Two normal bores are supplemented by slots that allow the housing to be shifted by a generous 4.5 to 13.5 millimeters.

More information on Ganter standard parts can be found in the internet at:

www.ganternorm.com